$54.00

This is sold by the linear yard.

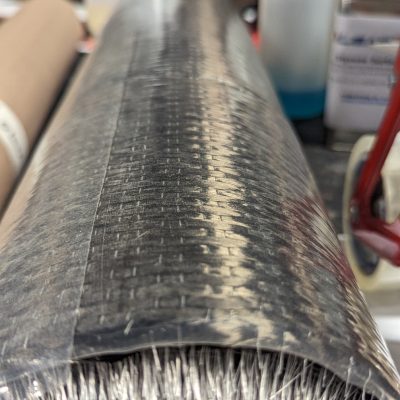

Width: 60″

Weight: 10.9osy

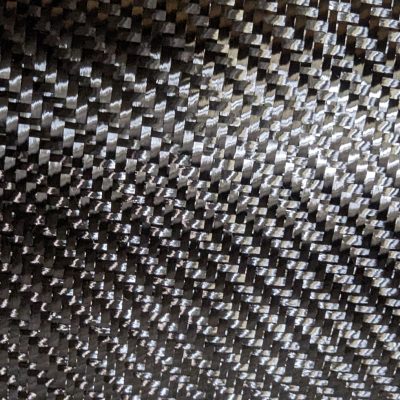

Weave: 8 Harness Satin

Tow Size: 3K

Thickness: .012″

Typical Tensile Strength, Modulus, Density of Carbon Fiber Available Here

Medium duty carbon for fast buildup and superior strength. Very dense 3K style weave keeps resin weights low but requires attention for proper resin saturation.

| Title | Range | Discount |

|---|---|---|

| 10.9oz - 3K - 8HS Carbon Fiber Fabric - (Yard x 60") | 5 - 9 | $2.05 flat $51.95 |

| 10.9oz - 3K - 8HS Carbon Fiber Fabric - (Yard x 60") | 10 - 19 | $4.55 flat $49.45 |

| 10.9oz - 3K - 8HS Carbon Fiber Fabric - (Yard x 60") | 20 + | $6.00 flat $48.00 |

ADDITIONAL INFORMATION:

Carbon fiber (carbon fibre), alternatively graphite fiber, carbon graphite or CF, is a material consisting of extremely thin fibers approximately 0.005-0.010 mm in diameter and made mostly of carbon atoms. The carbon atoms are bonded together in microscopic crystals that are more or less aligned parallel to the long axis of the fiber. The crystal alignment makes the fiber highly strong for its size. Several thousand carbon fibers are twisted together to form a tow, which may be used alone or woven into a fabric. Carbon fiber has lots of different weave patterns and can be mixed with a plastic resin and wound or molded to create composite parts such as carbon fiber reinforced plastic to yield a high strength-to-weight ratio material. The density of carbon fiber is also substantially lower than the density of steel, making it well-suited for applications requiring low weight. The properties of carbon fiber such as low weight, high tensile strength, and low thermal expansion make it very popular in aerospace, military, civil engineering, and motorsports, along with other competition sports. Unfortunately, it is relatively expensive when compared to similar materials such as fiberglass or plastic. Carbon fiber is very strong when stretched or in tension, but weak when compressed or exposed to high shock (e.g. a carbon fiber bar is very difficult to bend, but will crack easily if hit with a rock).

In 1958, Roger Bacon invented high-performance carbon fibers at the Union Carbide Parma Technical Center, positioned outside of Cleveland, Ohio. Those fibers were manufactured by heating strands of rayon until they carbonized. This process proved to be inefficient, as the resulting fibers had only about 20 percent carbon and had low strength and stiffness properties. In the early nineteen sixties, a process was developed by doctor Akio Shindo at Agency of Industrial Science and Technology of Japan, using polyacrylonitrile (PAN) as a raw material. This produced a carbon fiber that contained about 55% carbon.

The potential for high strength of carbon fiber was realized in 1963 in a process createdat the Royal Aircraft Establishment at Farnborough, Hampshire. The program was patented by the UK Ministry of Defense and licensed to three British companies: Rolls-Royce, already using carbon fiber, Morganite and Courtaulds. They were able to establish industrial carbon fiber manufacturing facilities within a few years, and Rolls-Royce took advantage of the new material’s properties to make a place in the American market with its RB-211 aero-engine.

Even with the advances, there were concerns over the ability of British industry to make the best of this breakthrough. In nineteen sixty nine a House of Commons select committee inquiry into carbon fiber prophetically asked: “How then is the nation to reap the maximum benefit without it becoming yet another British invention to be exploited more successfully overseas?” Eventually, this concern was fully realized. One by one the licensees stopped carbon fiber creation. Rolls-Royce’s interest was in the latest aerospace applications. Its own manufacturing method was to allow it to be leader in the use of carbon-fiber reinforced plastics. In-house manufacturing would generally cease once reliable commercial sources became available.

Sadly, Rolls-Royce pushed the state-of-the-art technology too far, too quickly, in using carbon fiber in the engine’s compressor blades, which proved vulnerable to damage from bird impact. What seemed a great British technological triumph in 1968 quickly became a disaster as Rolls-Royce’s ambitious schedule for the RB-211 was endangered. Rolls-Royce’s problems became so great that the company was eventually nationalized by Edward Heath’s Conservative government in 1971 and the carbon fiber production plant sold to form Bristol Composites.

Given the limited market for a very expensive product of variable quality, Morganite also decided that carbon fiber manufacturing was peripheral to its core business, leaving Courtaulds as the only big UK producer.

The company continued making carbon fiber, developing two main markets: aerospace and sports equipment. The speed of production and the quality of the product were improved.

During the nineteen seventies, experimental work to find alternative raw materials led to the introduction of carbon fibers made from a petroleum pitch derived from oil processing. These fibers contained about 85% carbon and had excellent flexural strength.

During the 1980s Courtaulds continued to be a major supplier of carbon fiber for the sporting goods markets, with Mitsubishi its main customer. Regrettably, a move to expand, including building a manufacturing plant in California, turned out poorly. The investment did not generate the anticipated returns, leading to a decision to pull out of the area. Courtaulds ceased carbon fiber manufacture in 1991, though ironically the one surviving UK carbon-fiber manufacturer continued to thrive making fiber based on Courtaulds’s precursor. Inverness-based RK Carbon Fibres Ltd has concentrated on creating carbon fiber for industrial applications, and thus does not need to compete at the quality levels reached by overseas producers.

Each carbon filament thread is a bundle of many thousand carbon filaments. A single such filament is a thin tube with a diameter of 5-8 micrometers and consists almost exclusively of carbon. The earliest generation of carbon fibers (i.e., T300, and AS4) had diameters of 7-8 micrometers. Later fibers (i.e., IM6) have diameters that are approximately 5 micrometers.

Precursors for carbon fibers are rayon, polyacrylonitrile (PAN) and pitch. Carbon fiber filament yarns are used in several processing techniques: the direct uses are for prepregging, pultrusion, filament winding, weaving, braiding, etc. Carbon fiber yarn is rated by the linear density (weight per unit length, i.e. 1 g/1000 m = 1 tex) or by number of filaments per yarn count, in thousands. For example, 200 tex for 3,000 filaments of carbon fiber is three times as strong as 1,000 carbon fibers, but is also three times as heavy. This count is usually expressed as 3K, 12K, 6K, etc. This thread can then be used to weave a carbon fiber filament fabric or cloth. The appearance of this fabric generally depends on the linear density of the yarn and the weave chosen. Some commonly used types of weave are plain, 2×2 twill, 4×4 twill and satin.

A common method of manufacture involves heating the spun PAN filaments to approximately 300 °C in air, which breaks many of the hydrogen bonds and oxidizes the material. The oxidized PAN is then placed into a furnace having an inert atmosphere of a gas such as argon, and heated to approximately 2000 °C, which induces graphitization of the product, altering the molecular bond structure. When heated in the correct conditions, these chains bond side-to-side (ladder polymers), creating narrow graphene sheets which finally merge to form a single, columnar filament. The result is usually 93-95% carbon. Low quality carbon fiber can be manufactured using pitch or rayon as the precursor instead of PAN. The carbon can become further enhanced, as high modulus, or high strength carbon, by heat treatment processes. Carbon heated in the range of 1500-2000 °C (carbonization) exhibits the highest tensile strength (820,000 psi, 5,650 MPa or N/mm²), while carbon fiber heated from 2500 to 3000 °C (graphitizing) exhibits a higher modulus of elasticity (77,000,000 psi or 531 GPa or 531 kN/mm²).

There are no reviews yet. Be the first one to write one.